Regional employers

Employers from trade and industry to information and consulting

Innovative companies - top-notch jobs

Eastern Upper Styria delivers ideas and technologies with great future potential. Many of these innovations are used all over the world. You probably use products on a regular basis that come from this region. Our greatest strength is materials technology. But eastern Upper Styria has additional perks that secure its place at the top of Austria’s industrial locations. A presentation of all successful companies would go way beyond the scope of this article, so we will just name a few of them.

Trade and industry

From mechanical engineering to electrical engineering - for skilled workers, eastern Upper Styria has always been a land of opportunity.

Industry and production

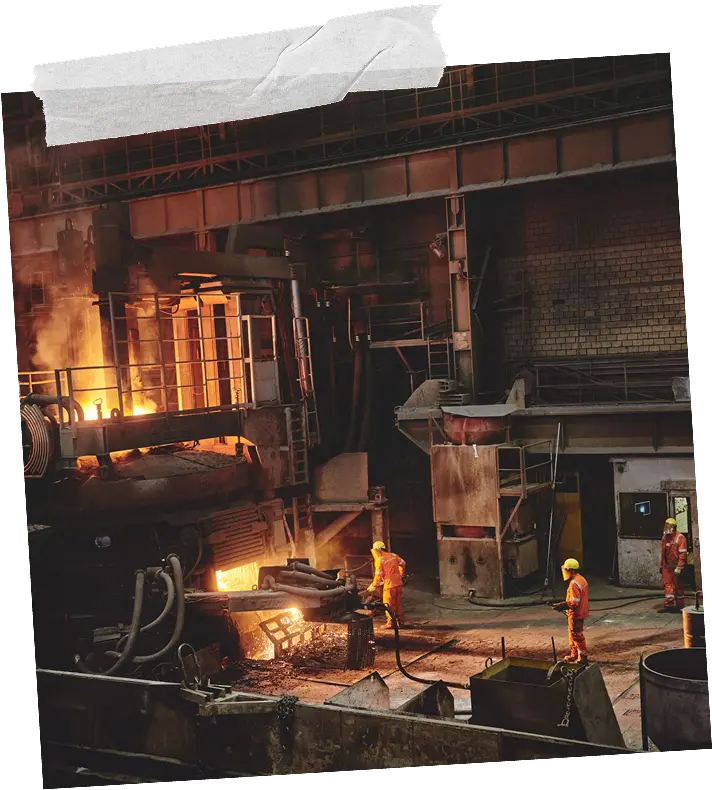

High-tech meets hands-on. Industry and production are the backbone of the region - with exciting jobs and strong future potential.

Science and research

From the Technical University of Leoben to the Materials Center Leoben - this is a region of research, development and design. It is an innovation power house.

Transport and traffic

We like to move it, move it! In the transport sector, companies from the region ensure that goods reach their destinations safely and just in time.

Retail business

Buy and work regionally. The retail sector provides numerous jobs and makes an important contribution to local value creation.

Health and social affairs

If you want to work with people, this is the right place for you. Meaningful work is a top priority in the health and social sector.

Information and consulting

Digital solutions, advice & know-how - innovation, technology and team spirit are key in this area.

Trade and industry

Experience, creativity and precision are all part of skilled work. From traditional trades to high-tech applications – many eastern Upper Styrian companies are pioneers in their sector. They offer apprenticeships, development opportunities and a professional home for skilled workers who like to get things done.

The 4a technology Group specialises in mobility, communication as well as traffic and vehicle safety. Its employees are experts in the simulation of plastic and composite materials, in the production of lightweight materials and sandwich composites as well as in the development and production of special test and sensor systems. Specifically, these are selected plastic products, test systems for material tests, dummies and systems for vehicle safety or parts for mobile phones – things we can’t do without in our everyday lives.

Benefits for employees: lunch, events and challenges, 4academy – training and further education, parental and educational leave, the option to work from home, flexible working hours, work clothing and state-of-the-art technical equipment, 4active&health, referral bonuses, car park and e-charging points.

Mettop is a relatively young company based in Leoben with an impressive portfolio. Founded in 2005 as an independent Austrian engineering company, Mettop specialises in technologies for metallurgical processes. In addition to the pyro- and hydrometallurgy of non-ferrous metals, innovative cooling systems for the iron and steel industry have recently been added to their programme. Technical advice, customer training and support in the risk management for plants are part of their range of services. There is even a Mettop Academy, which offers training courses and seminars on the subject of non-ferrous metallurgy.

Benefits for employees: 4-day week or 36 hours per week, involvement in challenging and varied projects at home and abroad, short decision-making processes and flat hierarchy (owner-managed company), extensive training and development opportunities, motivated, committed team, good working atmosphere.

The Hintsteiner Group in Kindberg is Austria’s leading competence centre for carbon and plastics technology in prototype and small series production. Since 1981, the owner-managed company has combined technological precision with innovative power and a genuine passion for customised solutions. On 3.500 m², two specialised divisions develop high-end components for industry, mobility and aviation. With the joint ventures Hilitech (aviation) and Carbon-Solutions China, Hintsteiner is also well-positioned internationally.

Benefits for employees: company canteen, early shift only, fitness centre, flexible working hours.

HILITECH develops the lightest cabin systems for business jets, with the clear aim of challenging gravity. As a joint venture between F/LIST and the Hintsteiner Group, this company from Kindberg has combined high-end interiors with expertise in lightweight construction since 2014. Creativity, understanding of materials and technological innovation create solutions that set standards in aviation. This delivers pioneering composite concepts for customers all over the world, made in Austria. Ignore gravity? Yes, HILITECH can.

Benefits for employees: flexitime models, home office, monthly meal allowance of 40 euros, excellent transport links, free employee car park, lively, family-friendly community with many events.

One fact is obvious: components for an airplane or a power station must be of the highest quality and withstand the highest loads. This is why they are manufactured in specialised production plants. Inteco special melting technologies GmbH designs and builds such plants. The high-quality stainless steel grades produced there are used in aircraft and turbine construction and other demanding areas.

Unlike its competitors, Inteco customises the individual plant types to the specific needs of its customers and does not sell standard plants “off the shelf”. These customised complete solutions have made Inteco the global market leader in special metallurgy. The company draws its expertise in materials from the region – for example in close cooperation with the University of Leoben.

Benefits for employees: health (free fruit, free use of paddle/tennis facilities), flexible working hours (36-hour week, 2 days home office (optional), flexitime), international activities, relaxed working atmosphere, flat hierarchies mean short decision-making processes, team events and team-building events, further training, meal allowance, 6th holiday week 6 years earlier.

When you braid your child’s hair, you probably won’t think of the automotive and aviation industries. Yet, the basic principle is similar. At the Mürzzuschlag-based company Secar, fibres are braided instead of hair. At the same time, these fibres are brought together with an adhesive under certain temperatures and cured. This innovative technology is known to experts as pul-braiding and is e.g. used by Airbus manufacturer EADS. Secar develops extremely hard-wearing carbon fibre components. Wing parts for the legendary Airbus A380 are also based on Upper Styrian expertise, as is the inner ring for the whispering engines of aeroplanes. And Secar can do even more: the film cassettes of the world’s largest camera manufacturer Arri also come from Mürzzuschlag.

In eastern Upper Styria, a lot revolves around industry. But certainly not everything, as is proven by the Pirker family. For more than 170 years, their name has been synonymous with the finest gingerbread. The company is as much a part of the pilgrimage town of Mariazell as the famous basilica. A love of tradition and craftsmanship are reflected in the family’s confectionery, wax moulding and distillery, which have been awarded the Styrian coat of arms. The owners, however, see no reason to rest on their laurels. That is why they are constantly creating new gingerbread varieties and flavour compositions. Currently, more than 400 specialities are made by hand in the gingerbread factories – with the support of modern technology. Enjoy a piece of it yourself soon.

Eastern Upper Styria is one of the most beautiful places to live. Many of the houses and flats here and in the neighbouring provinces are realised by a company from eastern Upper Styria – Kohlbacher. The product range includes semi-detached and terraced house projects, residential buildings and property developments. These include the new Europacity Leoben with 240 flats as well as office and commercial space. Kohlbacher does not use subcontractors. Almost all tasks are carried out by its 450 employees. A total of 12 business licences and 22 divisions are united under one roof. Entrepreneur Bernd Kohlbacher describes his team of long-serving employees as the backbone of the company. Every year, three to four apprentices start an apprenticeship in seven possible trades.

Benefits for employees: overpayment depending on qualifications, immediate entry possible, reliable employer, good working atmosphere, fair pay, company doctor, high-quality work clothing, quality tools, free parking, good transport links (S6), team events.

DMH Dichtungs- und Maschinenhandels GmbH is a global leader in sealing technology and metal-cutting plastics processing. For over 25 years, the family-run company has been developing innovative sealing systems, machines, components and tools – always with an eye to the future. DMH stands for quality, reliability and partnership-based growth. Customers, suppliers and employees appreciate the clear objectives: 100% performance, 100% solution, 100% satisfaction.

Benefits for employees: sports programme, discounted meals, home office, employee discounts, training and further education, team events.

Industry and production

Eastern Upper Styria is one of the strongest industrial regions in the country. From small family businesses to global corporations, products are created here that are used all over the world. Modern jobs, technical innovations and long-term prospects make the industry particularly attractive.

“Gold for ten years, silver for a hundred years or iron forever.” – According to legend, this was the water sprite’s offer to the people of Eisenerz. The clever people chose the latter, whereupon the water sprite showed them the Erzberg. To this day, it is considered the most important supplier of iron ore. VA Erzberg GmbH, which operates a sustainable mining operation, is responsible for mining. Over 230 employees work on ore extraction, processing and shipping. There are many reasons why the Erzberg is the largest and most modern mining operation in Central Europe. The extracted material is used as raw material for steel production.

In the meantime, tourism has become the second main pillar of VA Erzberg GmbH. Every year, around 50.000 guests visit the “Styrian loaf of bread” to get to know the miners’ world of work. Come along and be inspired by the Erzberg experience!

ESTET has been a reliable partner in steel and tank construction for over 35 years – family-managed, technically advanced and active throughout Austria. High-quality welded constructions made of structural steel, fine-grained steel and stainless steel are manufactured on a production area of 10.000 m² – from planning to commissioning. With special solutions for plant construction or turnkey industrial projects, ESTET stands for precision, flexibility and handshake quality. Around 300 company employees set standards in Austrian steel construction.

Benefits for employees: flexible working hours, good accessibility, varied work.

The construction of the second tube of the Gleinalm tunnel, the renovation of the Bosruck tunnel or a shaft project for a pumped storage power plant in the Swiss mountains are just some of the high-profile projects realised by Östu Stettin, part of the HABAU GROUP. With over 100 years of experience, there “ain’t no mountain high enough” for this Leoben-based company, whether it is the construction of tunnels, underground railways and shafts or the construction of the ÖBB Group headquarters at Vienna Central Station, the Mautner-Markhof-Gründe residential complex in Vienna with over 450 residential units, the Steweag-Steg logistics centre in Leoben and the renovation of the Massenberg tunnel. The company was even involved in the “Miracle of Chile”: Östu-Stettin provided the shaft access equipment for the rescue of the miners from a depth of 622 metres.

Benefits for employees: development opportunities at national and international level such as talent, management and leadership programmes, equal opportunities and transparency, sports & events, bonuses, flexible working hours.

Nothing is more annoying than a broken wear part, right? Be it in a household, in a car or in a workshop. That’s why Oerlikon Balzers Coating Austria GmbH aims to extend the service life of materials with a specially developed coating called BALINIT. It is extremely thin and resilient, is characterised by high hardness and reduces the friction that leads to wear. Every fourth PET bottle has a cap produced with Balzers-coated moulded bodies. Without Balzers coating, hardly any Formula 1 engine would be able to take to the track. And finally, every diesel injection pump contains a part coated with BALINIT.

The company is part of the global Oerlikon Balzers network with headquarters in Liechtenstein.

Benefits for employees: dynamic global culture, development opportunities, fair remuneration packages, further training.

What do the wheel suspension of the world’s largest dump truck, the turbine wheels in the world’s power stations and the adjustment parts of numerous oil rigs have in common? That’s right! They all use machine parts from eastern Upper Styria. The company Heldeco from Turnau is a manufacturing partner for numerous global players. It programmes, mills, turns, drills and grinds many special parts that contribute significantly to the functioning of the modern world. Even with machine parts weighing up to 60 tonnes, Heldeco can guarantee an accuracy of +/- 0.01 millimetres. In other words, the maximum deviation is 1 hundredth of a millimetre. Incidentally, this is based on the largest and most precise systems that are currently technically possible.

Benefits for employees: team spirit, short decision-making processes, state-of-the-art machinery and state-of-the-art premises, extensive on-boarding and training, challenging and varied tasks, numerous benefits, new employee premises, team events, secure and permanent workplace.

AT&S – which stands for Austria Technologie & Systemtechnik AG – produces 160 million printed circuit boards for mobile phones every year. An impressive number, best imagined in the form of 150 football pitches. Each year, 600 kilograms of pure gold are used in the production process.

AT&S printed circuit boards are an indispensable part of our everyday lives. They are not only found in mobile phones, but also in countless cars. All European premium car brands rely on high-tech printed circuit boards from Leoben for their navigation, multimedia and driver assistance systems. They are also used in tablets, aeroplanes and medical products such as hearing aids and pacemakers.

Benefits for employees: internationality, great work-life balance, development opportunities, international teams.

ALPINE is a NEPEAN company and a leading provider of engineering, consulting and equipment for continuous mining and bulk handling. The experienced team has developed over 200 machines and modernised over 100 systems worldwide. Whether it is a greenfield project, expansion or retrofit – ALPINE delivers customised solutions for complex systems with the toughest requirements. Technical expertise, global experience and innovative strength make ALPINE a strong partner for the heavy industry.

No matter what car you drive, there is a good chance that it contains special wire from Joh. Pengg AG. The wire from Thörl is used in most European cars. Pengg – one of the world’s leading suppliers of spring steel wire – specialises in products for the automotive, electrical and mechanical engineering industries. More specifically, these are drawn, oil tempered round and profiled spring steel wires. The products are characterised by the highest quality and performance. This is a prerequisite for valve and clutch springs, springs for injection systems, piston rings, tool springs, stamp springs and more. An exciting speciality product – straight from eastern Upper Styria.

Benefits for employees: training and further education, company events, bonuses, health promotion, free car park, cleaning of work clothes, healthy snacks.

Mayr-Melnhof Holz is one of the leading timber industry companies in Central Europe, based in Leoben and with strong roots dating back to 1850. MM Holz covers the entire value chain, from its own forest to modern timber engineering. As the market leader in glulam and a driver of innovation in the cross laminated timber sector, the family-owned company consistently invests in the future – most recently € 130 million at the Leoben production site. Sustainable, innovative and deeply connected to the region.

Benefits for employees: varied work, development opportunities, professional and personal training.

voestalpine Wire Rod Austria GmbH

From ore to wire: voestalpine Wire Rod Austria GmbH in St. Peter-Freienstein offers complete wire solutions from a single source. voestalpine Wire Technology is a leader in the production of wire rod, cold heading wire, flat and shaped wire, prestressing steel wire and strands, as well as ultra-high-strength fine wire. These products are used in the automotive supply industry, energy and construction technology as well as in mechanical engineering and railway infrastructure. voestalpine Wire Technology is a full-service provider of technical and economical wire solutions for innovative customers.

Benefits for employees: a culture of appreciation, employee participation, home office options, bonuses, flexible working hours, good transport connections, canteen, health management, sports & fitness programmes.

voestalpine Böhler Bleche GmbH & Co KG

Sheet metal that looks like wood? Hard to believe, but it does exist. The Mürzzuschlag-based company Böhler Bleche GmbH & Co KG supplies sheet metal that is used to produce pressed sheets for decorative laminates. These sheets are further processed into tools by highly specialised companies. Surface structures such as wood grains are etched into the sheet surface. These tools are used to press laminates, such as flooring or furniture panels. The etched surface structure of the pressed sheets is copied to the laminate surface.

A clever technology from eastern Upper Styria. Böhler attaches great importance to quality and precision in order to guarantee a long service life and problem-free use of these expensive tools.

Benefits for employees: employee participation, training and development programmes, company outings and team events, company physician, meal allowances, good transport connections, employee referral programme, bonuses, sports and fitness offers.

voestalpine Stahl Donawitz GmbH

Donawitz is one of the great names in the eastern Upper Styrian steel tradition. Whether in cable cars, high-tech railway tracks or in vehicles worldwide, the diverse services of voestalpine Stahl Donawitz GmbH can be found on every continent. Against this background, the steel forge has developed into a niche supplier for demanding product segments. The company scores with quality, environmentally friendly developments and the famous LD-process.

In Leoben, one of the most modern steelworks in the world, an incredible 1,6 million tonnes of steel and 500 different types of steel are produced every year. And it provides a great spin-off. voestalpine Stahl Donawitz uses its industrial waste heat to supply Leoben households with electricity and heat.

Benefits for employees: employee participation, training and development programmes, company outings and team events, social benefits such as health promotion, company restaurant, kindergarten/crèche.

voestalpine Schienen GmbH

We proudly present: the longest rail in the world. It is 120 metres long, used worldwide and comes from Leoben-Donawitz. Millions of people riding on trains or trams travel on rails made by voestalpine Schienen GmbH. Are you one of them? The special thing about these rails is their long service life. The extra-hard rails from Leoben last three times as long as normal rails. This reduces the environmental impact, maintenance costs and ultimately also disruptive construction work and speed restrictions sections.

With rails of this quality and quantity, voestalpine is the undisputed leader. Major railway companies such as ÖBB, Deutsche Bahn and the Swiss Federal Railways purchase their rails here. voestalpine Schienen GmbH delivers 7.000 kilometres of rails to all continents every year.

Benefits for employees: interdisciplinary and cross-cultural work, development opportunities and development programmes, exceptional team spirit, attractive working environment with flexible working time models, performance-related remuneration components, childcare, healthy snacks and more.

voestalpine Rotec

Despite modern vehicle technology, head-on collisions keep causing serious injuries. This makes it all the more important to wear a seatbelt at all times and have airbags ready to protect you. This is where voestalpine Rotec GmbH comes into play. The Krieglach-based company is fully committed to safety with its precision steel tubes. Decades of experience and international expertise make it a specialist in the development and production of tube components for restraint systems, such as formed precision tubes for belt tensioning systems. The side, head and knee airbags in our vehicles are also made from voestalpine Rotec tube components. It’s a good feeling to be able to rely on quality from eastern Upper Styria.

Benefits for employees: numerous health, fitness and sports activities, regular events organised by the works council, challenging tasks in an innovative company, further training opportunities and occupational health care.

voestalpine Tubulars GmbH & Co KG

These figures are hard to grasp. A total of around 350.000 tonnes of seamless tubes from Kindberg are supplied to the oil and gas industry worldwide on an annual basis. They are used as drilling, casing and production tubes. Not only has voestalpine Tubulars GmbH & Co KG enormous capacities to offer. It also provides innovative technologies. The special feature of the seamless tubes is that they have no potential breaking point. Secondly, they can be bent to a large extent. This means major advantages for the oil and gas industry. The seamless tubes from voestalpine Tubulars can also be further processed into anchor tubes, which are used to secure tunnel ceilings or walls. The possible applications are many and varied.

Benefits for employees: training and further education, company physician, flexible working hours, meal allowance, mental health promotion, home office, job bike, team events, employee referral programme, bonuses, discounts, employee participation, sports and fitness offers, great work-life balance.

voestalpine Böhler Welding Austria GmbH

The welding process is all about creating strong connections. voestalpine Böhler Welding delivers this, also in a figurative sense. The company has been shaping the development of welding technology for over 100 years with top-class welding consumables. As one of the leading manufacturers and suppliers of filler metals for industrial welding and brazing applications, the company is represented in 28 countries worldwide with 40 locations. Welding consumables from voestalpine Böhler Welding are used in industries around the globe, meeting high technical requirements, such as for oil & gas, chemicals and power generation.

The Kapfenberg plant is one of the most important production sites in the field of joint welding and specialises in filler metals for arc welding.

Benefits for employees: flexible working – smart working, long-term working relationships, employee participation, employee bonuses, health and safety programme, training and development, events.

voestalpine Böhler Aerospace GmbH & Co KG

voestalpine BÖHLER Aerospace GmbH & Co KG makes a significant contribution to ensuring that millions of passengers travel safely every day. The company supplies safety-critical components for all major aircraft programmes. In addition to the aviation industry, other high-tech industries also rely on the spot-on expertise from Kapfenberg. More than 200 customers source drop-forged parts made from titanium alloys, high-alloy steels and nickel-based alloys from here. All these parts are praised for their top quality and extreme resilience. voestalpine BÖHLER Aerospace GmbH & Co KG is both a supplier and a development partner to its customers. Complex tasks are not the exception, but the rule in the everyday work of the company’s specialists.

Benefits for employees: competitive remuneration packages and benefits, perks of all kinds, numerous sporting offers and activities, profit sharing, training and further education opportunities.

voestalpine Böhler Edelstahl GmbH & Co KG

You – and millions of other Europeans – have this product in your hands every day: stainless steel from Kapfenberg. Even though every country in the European Monetary Union mints its own Euro coins, almost all of them do so with Styrian hardness. Nine out of ten coins in Europe are moulded with Styrian steel. Böhler Edelstahl has developed a special cold work steel with extreme hardness and maximum durability so that the minting machines can eject 750 coins per minute with razor-sharp embossed images.

Impressive facts: The company supplies 200 different types of steel, is even active in the wind energy sector and has established itself as one of Europe’s largest suppliers of speciality steels. The annual production of Böhler Edelstahl amounts to 150.000 tonnes.

Benefits for employees: profit sharing, employee participation, personal development opportunities, further training programme.

Around 600.000 kilometres of optical fibres – 1,5 times the distance between the earth and the moon – and 150,000 kilometres of copper twin wires are processed in eastern Upper Styria every year. PENGG KABEL GmbH, which is based in Kapfenberg and Sankt Barbara im Mürztal, specialises in the production of cable infrastructure. At these two production sites, copper telecommunication cables, railway signal cables and fibre optic cables are produced according to special customer specifications. The company supplies the complete product range of passive fibre optic system components for the telecommunications and the railway industry. In addition, it offers assembly services in the field of copper and fibre optic technology, making it available to its customers as a full-service provider in the field of cable infrastructure.

Boehlerit is part of your everyday life. The company’s expertise in materials makes many products possible in the first place. For example, Boehlerit moulds give Euro coins their shape and appearance. There are many more examples. Aluminium cans are manufactured with Boehlerit deep-drawing rings, the rails of the Paris and London underground railways receive their final polish with Boehlerit tools and the gearbox and crankshafts at Daimler in Germany are also manufactured almost exclusively with Boehlerit tools and cutting materials.

Boehlerit can rightfully be called a carbide pioneer. It excels with innovations that minimise wear and tear. The expertise and tools from Kapfenberg are in demand all over the world.

Benefits for employees: a varied range of tasks in an international company, a crisis-proof job in a family-run business, health promotion, fruit day, company physician, car parks, company bikes, a pleasant working atmosphere and performance-related pay.

The history of Innoweld started way back in 1862 as a four-man business in a rented factory building. Today, it has grown into a globally active company with 130 highly specialised employees at its headquarters. Innoweld designs and manufactures industrial systems with a focus on pressure vessels and heat exchangers. Its services range from simple engineering and detailed engineering to the supply of large components and complete systems. The company’s many years of experience and the wide range of calculation and analysis tools are the basis for the outstanding quality and reliability of the end products. On top of that, the name Innoweld also stands for particularly short delivery times.

We know that there is a lot of oil buried under the sea. But how to get it up? It takes special oil production ships and high-pressure pipelines. Where to source them? Few people know that they come from Kapfenberg. BHDT GmbH (Best High Pressure & Drilling Technology) specialises in high-pressure systems and high-pressure components for the chemical and petrochemical industry. High-pressure pumps to pressurise a water jet tough enough to drill through glass, steel and even titanium, are also among the products of this top company. Last but not least, the plastics industry is supplied with various components for high-pressure systems. No matter what area of application, one thing is clear: BHDT always works with high pressure.

Benefits for employees: flexible working hours, training opportunities, career opportunities.

When you hear this name, you can stay cool. RHI Magnesita stands for products that withstand extreme temperatures of 1.200° C and higher. The company is the world market leader in the refractory sector. Its products are used in the steel, cement, lime, non-ferrous metals, glass, energy, environmental and chemical industries. RHI Magnesita’s refractory products keep various materials safe during processes such as melting, blasting, firing or moulding. They also protect firing and furnace systems from thermal, mechanical and chemical stress. From lining mixes to flow regulators, RHI Magnesita offers a total of more than 120.000 products. The basic materials used are magnesite and dolomite. The result is extreme resilience.

Benefits for employees: attractive remuneration packages including a global bonus programme, childcare facility (Hilfswerk) on the company premises, free parking incl. 12 charging stations, canteen with daily meal allowance, diverse health offers (mental & physical health platform, gym discount, sponsorship of sports events etc.), corporate benefits platform (incl. shopping discounts), RHIM Academy for your life-long learning and development, incl. full LinkedIn Learning catalogue, possibility of up to 50% home office time incl. allowance, flexible and trust-based working hours.

Imagine a gigantic block of steel. How heavy can it be? Well, if it comes from Breitenfeld Edelstahl AG, it could be up to 120 tonnes. These steel ingots are the largest of their kind in Austria and the company’s main product. Thanks to their special quality, they are used by the world’s best forges and ring rollers. Breitenfeld Edelstahl AG is the largest independent ingot supplier in Europe. The company is also active in the fields of special steel and forging technology. The Mürztal-based company is a niche player for high-quality stainless steel. Its products can be found almost everywhere in modern life, for example in wind turbines, shipbuilding, transport, the oil and gas industry, aerospace and surgical cutlery.

Benefits for employees: interesting, secure and long-term job, very good working atmosphere, highly motivated and innovative team, additional benefits in health management, further training opportunities, good transport links, accident insurance, leisure activities.

Good. Better. Gösser. Back in 1893, Max Kober laid the foundations for the development of one of Austria’s best-known breweries in Leoben-Göss. Today, as part of Brau Union Österreich AG, Gösser Bräu is an internationally successful company. Since 2016, brewing in Göss has been 100% CO2-neutral. What is more: 100% of the energy required for the brewing process at the Göss brewery comes from renewable forms of energy, 90% of the brewery’s own waste heat is recycled and a 1.500 square metre solar plant supplies the brewery with environmentally friendly solar power.

Benefits for employees: flexible working hours, meal allowance, occupational physician, development opportunities, home office.

Only the best drivers make it into Formula 1 – and only the best components make it into their cars. There is no racing car in Formula 1 that does not contain at least one component from the eastern Upper Styrian company Pankl Racing Systems. Premium vehicles from Porsche to Ferrari also feature Pankl expertise and the aviation industry also relies on Pankl products. Connecting rods, pistons, exhaust systems and wheel hubs, for example, are developed and manufactured for motorsports and the high-performance automotive sector. The company scores highly in these niche markets with lightweight construction at the limits of what is feasible and with materials that withstand even the most extreme loads. In addition to the branch in Bruck, Pankl is also based in Kapfenberg.

Benefits for employees: performance-related pay, flexible working hours, home office, diverse career opportunities, company canteen, health and fitness, team events, professional development, company flats, childcare support.

When you pick up the daily newspaper during breakfast on a Sunday, sift through the headlines, check the cinema schedule or analyse the results of yesterday’s football matches, you are probably holding a product from the Bruck-based company Norske Skog in your hands. With its ten factories – the headquarters being in Oslo – this paper group is one of the world’s largest producers of newsprint and magazine paper.

In Bruck alone, over 400.000 tonnes of paper are produced every year. This corresponds to around 700 full wide-bodied aeroplanes. The approximately 500 employees are constantly working on quality improvements in order to be successful on the global paper market – and they succeed: 75 per cent of the paper produced is exported.

Benefits for employees: canteen, car park, flexible working hours.

B&B is paper with a personality. As a leading manufacturer of labelling and packaging papers, Brigl & Bergmeister clearly identifies around 100 billion products every year – for brands that everybody knows. The mill in Niklasdorf has been in business successfully since 1890, with great expertise and a clear focus on quality and sustainability. Made in the heart of Europe, printed all over the world.

Benefits for employees: flexible working hours, company physician and company pension scheme, family-friendly shift model, further training, climate ticket, car park and good public transport connections.

The 4a technology Group specialises in mobility, communication as well as traffic and vehicle safety. Its employees are experts in the simulation of plastic and composite materials, in the production of lightweight materials and sandwich composites as well as in the development and production of special test and sensor systems. Specifically, these are selected plastic products, test systems for material tests, dummies and systems for vehicle safety or parts for mobile phones – things we can’t do without in our everyday lives.

Benefits: Mittagessen, Events und Challenges, 4academy – Aus und- Weiterbildungen, Eltern- und Bildungskarenz, Homeoffice Möglichkeit, flexible Arbeitszeiten, Arbeitskleidung und technisches Equipment auf neuestem Stand, 4aktiv&gesund, Empfehlungsprämien, Parkplatz sowie E-Ladeanschlüsse.

Retail business

From small specialist shops to international online retailers – the retail sector is a diverse field of employment. Customer contact, organisational talent and flexibility are in great demand. At the same time, the retail sector offers secure jobs and exciting career paths.

LIECO grows trees that last. Since 1985, the company from Kalwang has been cultivating high-quality forest container plants with a guarantee of origin. For forests that really take root. Whether in Austria, Germany or beyond, if you are looking for the highest growth rates, vitality and smart forestry, there is no way around LIECO. Research, technology and green passion make LIECO the market leader in Central Europe. And the forests’ best friend.

AURENA’s bid calling is quick, digital and has maximum reach. As the market leader in Austria, the platform has been auctioning off large quantities of goods in record time since 2012. Millions of bids, thousands of auctions, over 200,000 bidders from 50+ countries. It’s as exciting as live auctions. Whether fleet, warehouse or bankruptcy assets – with AURENA, space becomes value again. No hassle for sellers, guaranteed thrills for buyers.

Benefits for employees: exciting activities and independent work in a fast-growing, future-oriented company, further training, team-spirit and motivated colleagues, opportunity to contribute and implement your own ideas, IT equipment for private use, free drinks and lunch, team activities.

Transport and traffic

Reliable logistics, sustainable freight transport and technical sophistication – this is what makes the region’s transport and traffic industry so competitive. The range of businesses is impressive, from traditional companies to innovative system providers. You like to move it, too? Look no further.

20 countries. 140 international employees. 2.700 wagons in use and 2 million container unloadings per year. That’s Innofreight, a Bruck-based company that develops innovative wagons, containers and unloading systems for and with its customers. Innofreight has been awarded multiple times for its innovative logistics and mobility concepts. Today, the Bruck-based company’s modular transport systems are used in a wide range of industries from Finland to Portugal.

Benefits for employees: internationality, flexible working hours, continued training, company outings, sports, meal allowance.

Whether it is transporting tarpaulins, hauling machinery or realising civil engineering projects – Brandl Transport-Logistik from Trofaiach gets things moving. The family business has been successfully expanded since 1905 and today offers customised national and international logistics solutions. With a modern fleet of vehicles, its own workshop and fleet of excavators, Brandl has a solid base – reliable, flexible and always ready for the next challenge.

Benefits for employees: varied tasks and challenges, team spirit, positive working atmosphere, attractive remuneration packages for employees.

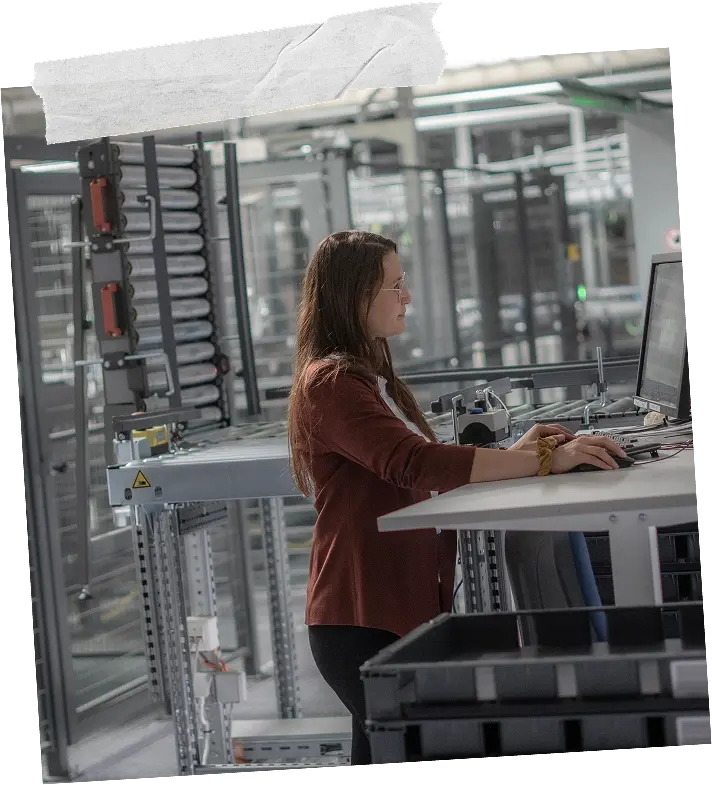

Information and consulting

If you have a passion for thinking, analysing and giving advice in a networked way, this industry is for you. IT solutions, business know-how and strong communication skills are sought after. Companies need creative minds and committed teams to thrive.

TDE has been a pioneer in data-based technologies and sustainable solutions in the energy sector for over 23 years. The company develops smart systems for more efficient operation and supports the transition to green energy, with a focus on hydrogen and carbon solutions. With its innovative spirit and industry know-how, TDE is actively shaping the future of energy.

Benefits for employees: home office, work in international teams, team events, global assignments including business trips, continued training and good development opportunities, free snacks and drinks.

No matter how you like to keep things organised. In warehouse logistics, you always need a concept. The specialist Knapp Systemintegration GmbH creates comprehensive logistics concepts for complex and largely automated warehouses. The logistical challenges behind this are tremendous. Knapp manages them with creative and innovative solutions. Consultancy, planning, programming, production, installation and commissioning as well as technical support and staff training make up the service package delivered by Knapp. This results in customised logistics systems for selected industries such as food and beverages, tools, office supplies and mail order.

Benefits for employees: exciting challenges in an attractive working environment, great work-life balance, freshly cooked meals every day in the company restaurant, KNAPPvital company health and well-being programme, flexible working hours, training opportunities for professional and personal development, excellent career prospects.

Health and social affairs

Work with passion and expertise. In the health and social sector, it is all about people. Whether it is nursing, therapy or care – professionals do valuable work every day that makes a big difference in other people’s lives. This industry offers purposeful, future-proof and significant work.

The Public Regional Hospital (LKH) Hochsteiermark is a modern healthcare provider with three locations: Bruck, Leoben and Mürzzuschlag. It provides the best possible medical, nursing and technical care with a patient-based approach. Sustainability, quality and regional strength make the LKH a reliable partner for healthcare in the region.

Benefits for employees: long-term prospects and job guarantee in a crisis-proof company, working in a good team atmosphere at eye level and with appreciation, automatic advancement in the salary scale every 2 years, paid lunch breaks, 6th week of holiday for everyone aged 43 and over, plus an additional week of holiday for medical staff.

The Bruck-Mürzzuschlag Care Association is the largest provider of inpatient care for the elderly in the region. Around 800 residents and day guests are attended to in 8 nursing homes and 2 day-care centres – human, skilful and with long-standing experience. More than 650 employees provide professional care with a human touch every day. As a public organisation, the care association focuses on innovation, quality and strong regional roots.

At NTK Kapfenberg, care, therapy and medicine go hand in hand – individually adjusted and in constant dialogue. The focus is on providing the best possible support on the way back to an independent, healthy life. With comprehensive care, specialised therapies and modern functional diagnostics, the NTK supports people in their neurological rehabilitation.

Benefits for employees: family-friendly part-time jobs, support in finding accommodation if necessary, free back exercises, relaxation groups, short-term endurance training, individual and group supervision, free milk, free fruit baskets and drinking water vending machines, generous opportunities for internal and external training and further education.

Science and research

This region comes up with future solutions. Science and research generate fresh ideas, bright minds and innovative technologies. Whether at the Technical University of Leoben, at the UAS JOANNEUM Kapfenberg, in research centres or development departments – solutions for tomorrow are created right here.

MATERIALS is part of JOANNEUM RESEARCH, a leading non-university research organisation based in Graz. Around 500 employees at six locations develop technological solutions for society, business and industry. At the Niklasdorf and Leoben sites, the focus is on innovative processes such as laser and plasma technologies, 3D printing and modern production technology – always with the aim of implementing research into marketable applications.

Benefits for employees: room for individual career paths, personal development, a meaningful job, flexible working hours, training opportunities, team spirit, appreciative working atmosphere.

At FH JOANNEUM Kapfenberg, everything revolves around health, technology, sustainability and digitalisation. Whether full-time, dual or part-time – modern study formats, practical teaching and strong business partners ensure premium education. Future topics such as Industry 4.0 and AI are just as much a focus as green transformation or healthcare and nursing. Those who study or work here are actively involved in making innovation happen.

Benefits for employees: attractive and flexible working conditions, a family-friendly environment, personal development, transparent remuneration, further training opportunities, mobile working, fixed or event-related teleworking days, flexitime arrangements, 1 week of childcare during the summer holidays, sports facilities.

At the Technical University of Leoben, research becomes the future. It is not just the slogan. This top university with its headquarters in the second largest city in Styria is tackling the environmental challenges of the future in research and education. The degree programmes focus on the entire value creation cycle. The five core values of energy efficiency, climate neutrality, sustainability, zero waste and circular design are omnipresent underlying themes.

Benefits for employees: flexibility, fair and transparent remuneration, benefits such as a canteen and health measures.

Have you always wondered how large amounts of energy can be stored reasonably and over a longer period of time? How a rail switch can withstand a heavy goods train? Why and when a mould breaks? Materials Center Leoben Forschung GmbH (MCL) gets to the bottom of these questions. We develop and test materials, their manufacturing processes and a wide range of applications in mechanical engineering, energy technology and microelectronics. In addition to a wide range of simulation tools for computer-aided modelling of materials, we have state-of-the-art testing facilities and well-equipped laboratories for materials testing. Topics such as digitalisation, BigData and GreenDeal are not merely a vision of the future. We live, research and develop them!

The Polymer Competence Center Leoben (PCCL) is Austria’s leading research centre for plastics technology and polymer science. Since 2002, the PCCL has been working with industry and universities to develop pioneering solutions, from mobility and packaging to photovoltaics. Around 100 experts work on R&D projects that make innovation measurable and make plastics smarter, more sustainable and more efficient.