UAS JOANNEUM Kapfenberg

Technology, sustainability and healthcare professions – at UAS JOANNEUM Kapfenberg, insightful teaching meets practical research. Around 1.000 students and more than 200 lecturers are actively involved in shaping the region’s economy and living environment. State-of-the-art laboratories, international networks and strong business partners make the location a hotspot for innovation in eastern Upper Styria.

Facts & figures on the Kapfenberg location

Werk-VI-Straße 46

Wiener Straße 25

(2024/2025)

Josef Ressel Zentrum Kapfenberg

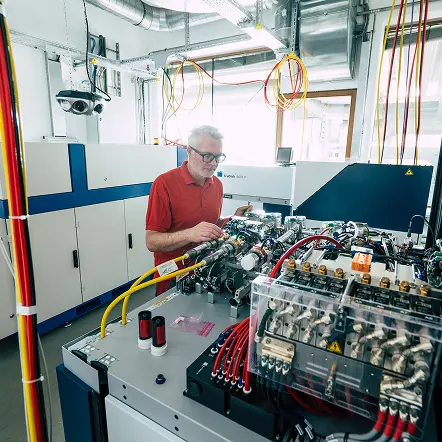

What if machines could predict their own failures? This is exactly what the Josef Ressel Zentrum in Kapfenberg works on. The aim is to use data-based models to recognise – and prevent – failures at an early stage. The centre was opened in 2024 and is funded by the Federal Ministry of Labour and Economic Affairs (BMAW) and the Christian Doppler Research Association. Corporate partners include AVL DiTEST and voestalpine Tubulars.

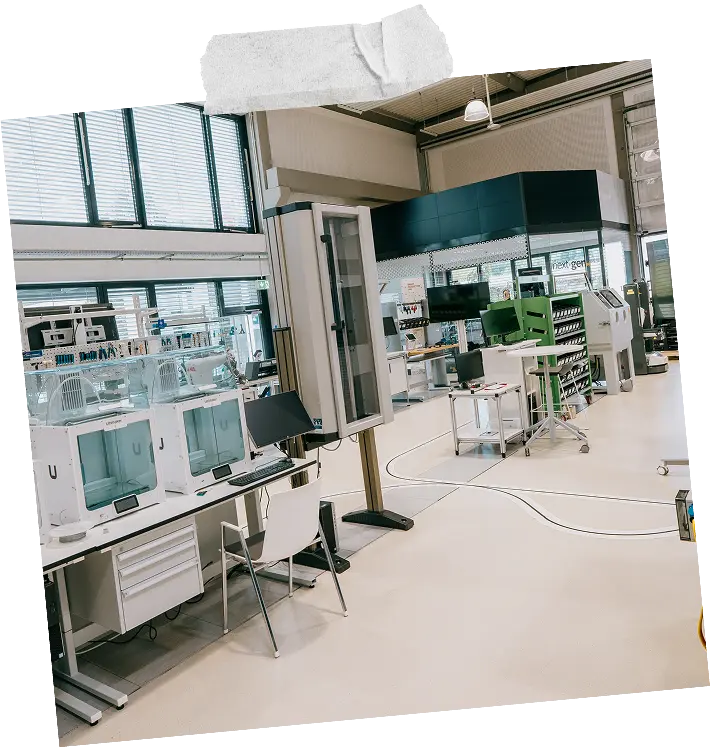

Smart Production Lab

The Smart Production Lab at UAS JOANNEUM is a laboratory for applied digitalisation.

- 600 m² area, 7 m hall height

- Investment: 3.5 million euros

- 20 Partners from business & research

- Focus on Industry 4.0, SCM, ERP/MES

- 15+ years of research experience

This is where digital solutions for the production of tomorrow are created – networked, practical and innovative.

Experience Industry 4.0 - guided tour

Monthly guided tours make Industry 4.0 tangible. From the Industrial Internet of Things (IIoT) to digital retrofitting and big data – visitors experience cutting-edge technologies and application examples for digital transformation up close. Companies learn how to optimise processes and integrate future technologies in a meaningful way.

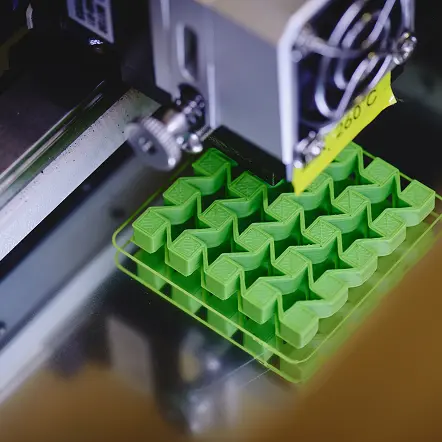

Experience Industry 4.0 - Fab Lab

The FabLab makes ideas come alive. The open high-tech workshop is equipped with 3D printers, laser cutters, milling machines and more and invites you to experiment. Whether it is done by students, other creative minds or inventors – prototypes, projects and lots of expertise are created here. Join in, think ahead and try it yourself.

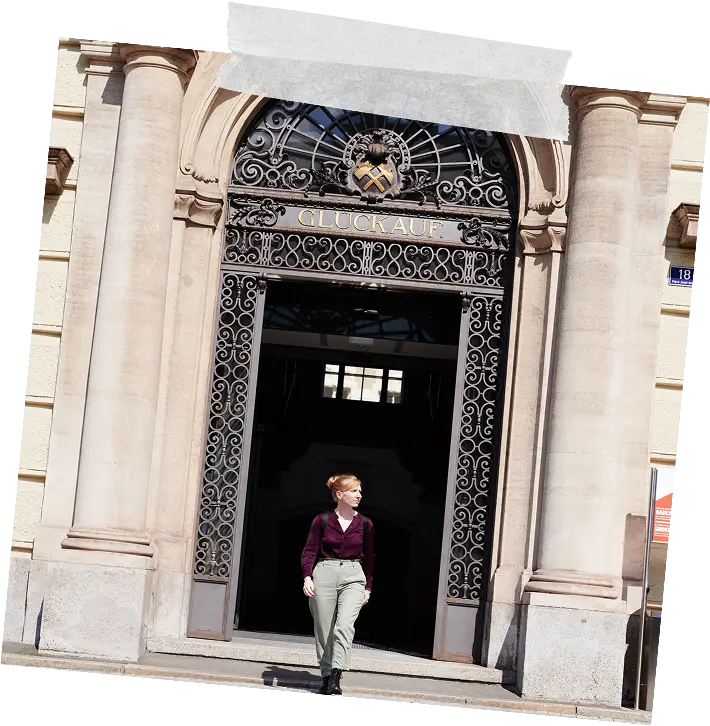

Technical University of Leoben

The highly respected Technical University of Leoben is the cradle of remarkable achievements. It not only educates excellent technicians, but also delivers down-to-earth innovations that benefit both the industry and the environment. This is where research becomes education. It is why this university has won international acclaim.

Do you want to help change the world and protect the environment? At the Technical University of Leoben you can not only study. You can also advance materials research and become one of 400 researchers. Be a contributing part of this huge team of brilliant minds. To the location:

Research centre for hydrogen and carbon

The new research centre for hydrogen and carbon in Leoben is a milestone for sustainable technology development. Since October 2024, science and industry have been working together on the climate-friendly use of two key elements of the future: hydrogen and carbon.

The focus is on the CO₂-neutral production of hydrogen and solid carbon through methane splitting, the refinement of carbon for agriculture and the utilisation of biomass residues. The use of hydrogen in metallurgical processes is also being driven forward, supported by partners such as Graz University of Technology, RAG Austria AG and Inteco GmbH.

The goal is to develop technologies that run on renewable energies, reduce CO₂ emissions and to develop new application possibilities, from the field to the industrial plant. Research is also being conducted into how carbon improves soil quality and thus increases yields and the climate resistance of plants.

This way the centre is making an essential contribution to the transformation of industry, energy and agriculture, while at the same time strengthening climate protection for future generations.

ZAB – Zentrum am Berg

Underground research, development, training and education on a 1:1 scale. At the Styrian Erzberg mine, the Technical University of Leoben operates an independent research infrastructure for the construction and operation of underground facilities that is unique in Europe.

Research institutions, companies and organisations have the opportunity to carry out research, tests and exercises under real conditions for operators and users of road and rail infrastructures as well as on aerodynamic issues, safety in underground construction and operation and material developments.

The underground facility consists of a twin-tube road tunnel and two parallel railway tunnels as well as a test tunnel, enabling research, development, education and training under real underground conditions.

Now that the construction work has been completed, it is possible to use a motorway and a railway tunnel on a 1:1 scale for a variety of purposes.

Further top addresses for research & innovation

Research companies & competence centres

The federal government’s “COMET” competence centre programme aims to strengthen cooperation between industry and science and to promote the development of joint research expertise and its scientific and commercial exploitation. The Technical University of Leoben is involved in the following centres of competence in Leoben:

Materials Center Leoben (MCL)

The Materials Center Leoben (MCL) is an internationally established research company specialising in materials, manufacturing and processing as well as innovative material applications. The focus is on metallic and ceramic materials and their composites.

- 63% COMET-funded research

- 20% non-COMET funded research

- 17% non-COMET revenues from the economy

- 150 employees

- 135 publications

- 199 press reports

Innovations from the MCL

How do ideas become real-life innovations? The MCL shows what is possible.

Sustainable corrosion protection

The Materials Centre Leoben replaces paint-based corrosion protection with deep rolling - environmentally friendly, resource-saving and low-maintenance.

Polymer Competence Center Leoben GmbH (PCCL)

As a leading research centre for plastics technology, PCCL has been developing innovative polymer solutions since 2002 – from automotive, aviation and packaging to solar and photovoltaic applications.

- COMET Centre K1 budget (2024-2028), EUR 22,6 million

- Turnover 2023, around EUR 10,6 million

- Around 100 employees

- 15 patents

- 521 publications in referenced journals

Innovations from the PCCL

As a competence centre for plastics technology, the PCCL develops innovative methods to repair things instead of replacing them. This is proven by 2 best ofs.

Repaitecture

New technologies enable targeted repair instead of replacement - resource-saving and durable.

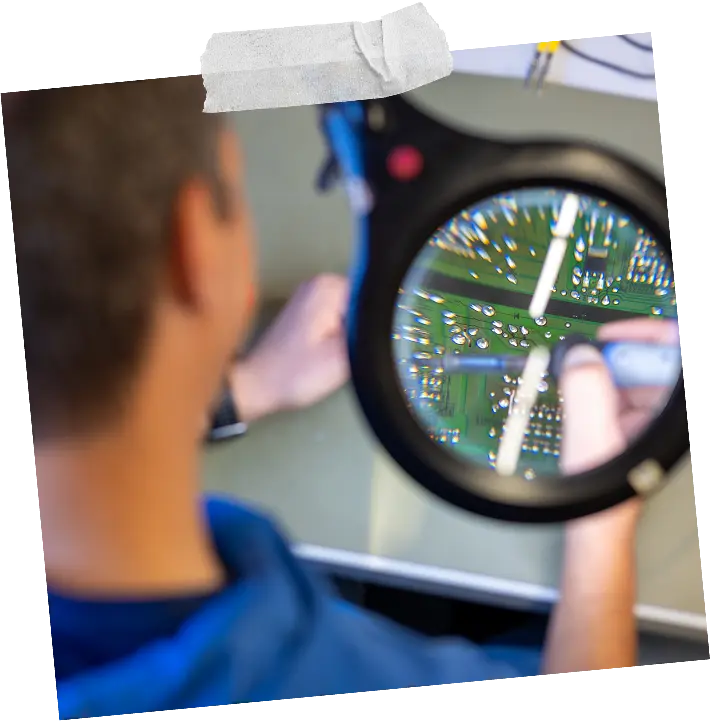

Battlab

Research for robust batteries. Intelligent concepts improve safety and extend service life.

Joanneum Research

JOANNEUM RESEARCH develops solutions and technologies for business and industry in a wide range of sectors and conducts cutting-edge research at an international level. The Niklasdorf site in Upper Styria is part of the JOANNEUM RESEARCH Institute MATERIALS (Institute for Sensors, Photonics and Manufacturing Technologies). At Niklasdorf, around 20 researchers develop materials, processes and coatings using lasers (100 W to 8 kW) as well as plasma-based surface and coating technologies for a wide range of industrial applications such as metalworking, energy generation, aviation, automotive engineering and medicine.

Innovations from Joanneum Research

Research for practice: JOANNEUM RESEARCH develops pioneering technologies in Niklasdorf - from laser processes to intelligent surfaces for industry, energy, mobility and medicine.

Innovative materials for aviation

MATERIALS develops lightweight, robust materials for more efficient aircraft and sustainable technologies.

Green steel

Innovative processes from Niklasdorf reduce emissions in steel production - a step towards the climate-friendly industry of the future.